Press release 2019-11-14 at 8:39

The responsible scientist for UBINAM project Hermanni Kaartokallio lifting the experimental device from the sea near the University of Helsinki Tvärminne Research Station in January 2019. The device was stationed in approximately ten meters depth in free water above the seafloor. © Eeva Eronen-Rasimus/SYKE

The Finnish Environment Institute (SYKE) has studied how biodegradable and bio-based materials actually decompose in the Baltic Sea marine environment. The research programme comprised a set of year-long tests in the sea. Some materials decomposed almost completely within six months, while others decomposed not very much at all in the course of the entire year.

Biodegradable and bio-based plastics are increasingly being used in packaging and in disposable and consumer products. It is well known that ordinary plastics may survive in the environment for anything up to centuries and fragment into microplastics. In a marine environment, plastics may migrate long distances, accumulating on shores and in mid-ocean vortices, causing harm to marine life and to the marine environment. As biodegradable plastics become increasingly common, the risk of them ending up as marine litter also grows.

Many kinds of bioplastics

Bioplastics are a diverse material group. Biodegradable plastics are manufactured from both bio-based and non-renewable fossil raw materials. Bio-based raw materials are also used to manufacture conventional plastics, such as bio-polyethene, which are not biodegradable. For consumers, it is difficult to perceive how various materials behave when they end up in the environment.

As of yet, there is little research data available on how commonly used biodegradable plastics decompose in marine environment, and there are no comprehensive decomposition standards against which the behaviour of materials in the environment could be measured. The offering of bio-based and biodegradable products is increasing, and their use is growing. Information on material properties is important in selecting applications for them, and this is of interest to consumers too.

Decomposition is often slower in the environment than in industrial composting

A biodegradable material exposed to the environment is decomposed by naturally occurring microbes into carbon dioxide and water. For the most part, this process has only been observed in industrial composting.

“In industrial composting, the circumstances – temperature, oxygen level, decomposer microbe communities– are optimal for decomposition. In a natural environment such as the sea, the circumstances are not as ideal, and thus decomposition is slower than in industrial composting,” says Senior Researcher Hermanni Kaartokallio from SYKE.

Kaartokallio and his research team have studied how bio-based and biodegradable film materials in common use and certain experimental materials actually decompose in the Baltic Sea marine environment. The research programme involved one year of tests in the sea and in the laboratory. SYKE was partnered in the project by three Finnish companies in the sector: Sulapac Oy, Walki Plastiroll Oy and Paptic Oy. The Ministry of the Environment of Finland provided EUR 200,000 in funding for the project. The project supports the programme of measures for the Finnish marine strategy.

Commonly used and experimental materials tested

The reference materials in the study were three commonly used bio-based biodegradable films: polylactide (PLA), polyhydroxyalkanoate (PHA) and cellulose acetate, or cellophane. The other materials studied were polyethene film, the Bioska film manufactured by Walki Plastiroll, and Paptic and Sulapac experimental materials. The experimental materials tested were fibre–biopolymer materials and wood–biopolymer composites; their exact composition is known only to their manufacturers.

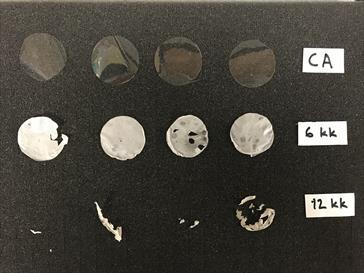

The material samples were immersed in the sea off the south-western coast of Finland for periods of six months and 12 months. Some of the materials decomposed almost completely within six months.

“The fastest to decompose were PHA, Bioska film and certain Paptic experimental materials. After six months, there was nothing left of them. Biodegradable cellulose-acetate film decomposed mostly over the course of the year, but PLA hardly decomposed at all. The polyethene films were as good as new after one year in the sea,” says Kaartokallio.

Cellulose acetate used in the study was of biodegradable type. During the experience it lost mass by degradation and corrosion of surfaces. After a year most of the material was degraded. The picture shows new foils (upper row) and foils submerged for six (middle row) and twelve months. More pictures of different materials in the end of this press release. © Hermanni Kaartokallio/SYKE

Decomposition depends on shape as well as material

Decomposers attack a material on its surface. The rate of decomposition depends on the shape of the item, the thickness of the material and how it disintegrates into smaller pieces during the decomposition process. Thin film will decompose faster than thick film, and if the material disintegrates, allowing the ingress of water, the decomposition process is accelerated.

Actual decomposition into carbon dioxide and water was confirmed in one-month long laboratory tests. Two materials from each partner enterprise were selected for laboratory testing. The reference materials, the Bioska materials, Paptic experimental materials and one Sulapac experimental material were included in both sea and laboratory tests. In the laboratory tests, the materials were ground to a fine powder before testing. The findings were consistent with the field tests: depending on whether the materials decomposed rapidly or slowly in the sea, they decomposed rapidly or slowly, respectively, in the laboratory. The only exception to this was one of the two Sulapac experimental materials, which was only tested in the laboratory and which decomposed very rapidly. The Sulapac materials tested in the sea, sheet-like and dozens of times thicker than the other materials tested, decomposed fairly slowly, losing only up to 7% of their weight in a year.

Biodegradable products and packages should be recycled

The project only involved testing a handful of materials, and then only in one environment, viz. open water. Plastic waste also ends up in seabed sediment and on shores.

“Our findings indicate that not all bio-based biodegradable plastics decompose rapidly in a marine environment. Therefore, even if a product or package is biodegradable, it should not be disposed of in the environment; it should be recycled just like ordinary plastic,” says Kaartokallio.

Some biodegradable plastics do decompose with evident rapidity in a marine environment and have only a short-term environmental impact compared with conventional plastics. The materials that were found to decompose rapidly in the SYKE study were made of polymers naturally produced by plants or bacteria.

The EU Single-Use Plastics Directive will prohibit entire categories of products, such as disposable cutlery, plates and drinking straws, and mugs and single meal packaging made of expanded polystyrene (EPS) or styrofoam, as of July 2021. The Directive also aims to curb significantly the use of certain products such as disposable plastic mugs and single meal packaging. Under the Directive, products to replace the prohibited products may only be manufactured using unmodified naturally occurring polymers (e.g. cellulose, chitin). The Commission is currently working on guidelines. The findings of the SYKE study indicate that focus on the use of naturally occurring polymers is justified.

Further information:

- Senior Researcher Hermanni Kaartokallio, Finnish Environment Institute, tel. +358 50 325 7580, firstname.lastname@ymparisto.fi

- R&D Director Jani Avellan, Walki Plastiroll Oy, tel. +358 40 759 2000, firstname.lastname@walki.com

- Sustainability Director Maija Pohjakallio, Sulapac Oy, tel. +358 50 595 6891, firstname.lastname@sulapac.com

- Sustainability Manager Daniela Bqain, Paptic Oy, tel. +358 40 763 6962, firstname.lastname@paptic.com

Pictures for Media use: